Daijin Blue - Eye Candy Pigments

Code: 3972/000005 3972/000025 Choose variantProduct detailed description

Daijin Blue is an intense blue pigment from our Glow Series. This bright blue pigment charges under light and provides up to 8-10 hours of continuous glow in the dark. It’s a great choice for anyone looking to add a unique glowing effect to their creations.

Glow in the Dark pigments have a higher density than regular pigments, requiring smaller containers. When mixed with other pigments, its glow ability is reduced, yet it still creates a unique light effect. Daijin Blue is ideal for a variety of creative projects, from epoxy resin to slime and jewelry crafting.

This blue pigment brings vivid color to everything from bath bombs and candles to acrylic paints and cosmetics. Add an unforgettable touch to your DIY projects with Daijin Blue.

Technical parameters and information

Ingredients and Particle Size

- Particle size : 30-50 μm

- Ingredients : Strontium Aluminate, Polyurethane-11, Ultramarine Blue

- Heat Threshold:752 °F - 1112 °F (400 °C - 600 °C)

Additional Data

- Product Type : Mica

- Vegan : Yes

- Soaps : Yes

- Epoxy Resin : Yes

- Acrylic : Yes

- FDA-Permitted for External Use : Yes

- FDA-Permitted for Eye Area Use : No

- FDA-Permitted for General (Including Lips) Use : No

- FDA-Permitted for Bath Bombs Use : No

How to Mix Pigments Properly – Tips and Tricks

Tip how to mix NEON and Glow In the Dark pigments in resin

Neon and Glow In the Dark pigments are very fine and mixing in resin is very difficult. Here is a sample procedure on how to proceed.

- Put the required amount of pigment in a clean container

- Add 91+% Isopropyl alcohol and mix the pigment

- Add your favorite epoxy resin and mix thoroughly

Mixing with epoxy resin

The most common question we receive is: “How much pigment per liter of epoxy?” This is a very valid question, but unfortunately, there is no definitive answer due to the various types of applications and variations.

- Therefore, we recommend 1-2 grams per 1000 ml, and add more as needed.

For example: Are you aiming for an opaque or transparent look? Lighter colors may require more pigment to achieve the desired shade.

Why micron sizes matter

Please be aware of the pigment’s micron size. The larger the micron, the larger the particle. Typical pigments have an average particle size of 10-60 μm. Note that larger micron-sized pigments will likely have a heavier density, causing the pigment to sink faster in fresh epoxy, such as in deep pours. For example, our Icicle or 14k Nugget Gold pigments have a size of 200-700 μm and will likely sink faster in fresh epoxy. To prevent sinking, let the epoxy settle a bit, or return to your project and “stir” it again.

How to Use Pigments for Soap Making

Pigments are often used to color soaps, whether using the cold process or hot process methods. Choosing the right pigment and optimal ratio is key to achieving an even and vibrant color without altering the soap’s texture. Pigments allow for a wide range of shades, from subtle to intense, with easy adjustment of the amount depending on your needs.

To achieve perfect results, it’s important to follow the correct ratios. Using too much pigment can change the texture of the soap or cause excessive coloring during use. The following recommendations provide a starting point for precise pigment mixing, with the option to adjust the pigment amount as needed.

Recommended Mixing Ratios

- Cold process: Use 2 teaspoons of pigment per 1 lb (450 g) of oils.

- Hot process: Use ½ teaspoon of pigment per 1 lb (450 g) of melt-and-pour soap base.

Following these ratios will give you vibrant colors and even pigment distribution in your soap. Pigments are an excellent choice for producing naturally colored soaps without affecting the structure or quality of the final product.

This method is perfect for those who want to create personalized soaps with a professional look and long-lasting color.

How to Use Pigments for Automotive – Ratios and Tips

DO NOT USE! Neon pigments are not recommended for automotive use because they have low UV resistance. This means that when exposed to sunlight for extended periods, the pigments may fade or lose their vibrancy over time. UV rays can cause the colors to deteriorate, which is why these pigments are best used in applications that are not subject to prolonged sunlight exposure.

How to Use Pigments with Acrylic Paints – Ratios and Process

Pigments are widely used to create colorful effects in acrylic pouring. Proper pigment mixing with acrylic paints ensures a smooth and even result without clumps or bubbles. When pouring acrylic, it’s crucial to follow the right steps for preparing the pouring medium, dissolving the pigments, and blending them with the medium. This process will give you the perfect color and consistency for your creative projects.

Recommended Process for Mixing Pigments with Acrylic Paints

Step 1: Preparing the Pouring Medium

- Mix 3 partsBehr8300 Deep Base interior/exterior Hi-Gloss Enamel with 1 partJOSONJA Polyurethane Water-Based Gloss Varnish.

- Stir gently to minimize bubbles. Ensure the paint and varnish are completely mixed.

Step 2: Dissolving Pigments in the Medium

- Pour ½ to 1 teaspoon of JOSONJA Gloss Varnish into a container.

- Add around 1 teaspoon of pigment (or a bit more) and stir until the pigment dissolves completely, making sure to eliminate any clumps.

Step 3: Combining the Pouring Medium and Dissolved Pigments

- Add 3 tablespoons of the pouring medium to the dissolved pigments.

- Mix thoroughly, folding slowly rather than whipping to minimize air bubbles.

Step 4: Adjusting Consistency

- If the mixture is too thick: Add a small amount of JOSONJA and stir until the desired consistency is reached.

- If the mixture is too thin: Add a small amount of Behr8300 and stir until you achieve the correct consistency.

This process will ensure a consistent color and smooth surface, free of air bubbles, which is essential for successful acrylic pouring.

Additional parameters

| Category: | Metallic pigments that glow in the dark |

|---|---|

| EAN: | Choose variant |

| Color: | Blue |

| Particle Size [μm]: | 30-50 |

Bright orange glow-in-the-dark pigment with up to 10 hours of shine. Perfect for resin, acrylics, jewelry, slime, and more glowing projects.

Bright green glow pigment perfect for epoxy, acrylics, jewelry, slime, and decor. Charges with light, glows for 8-10 hours.

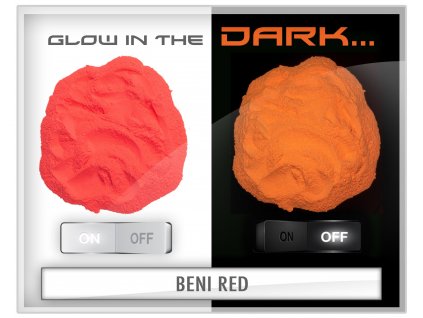

Red glowing pigment with an 8-10 hour glow. Perfect for resin, acrylics, jewelry, slime, and other nighttime projects.

Vibrant orange pigment with a long-lasting 8-10 hour glow. Perfect for epoxy, acrylics, jewelry, slime, and other creative projects.

Bright pink pigment from the Glow Series, glowing for 8-10 hours after light exposure. Perfect for resin, acrylics, candles, and cosmetics.

Intense purple glow-in-the-dark pigment. Charges with light, perfect for epoxy, acrylics, jewelry, slime, and more lasting creative projects.

Daishin Yellow is a yellow based bright yellow green pigment and part of our Glow Series line. Our popular mica powder is ideal for DIY craft use, such as, epoxy,...

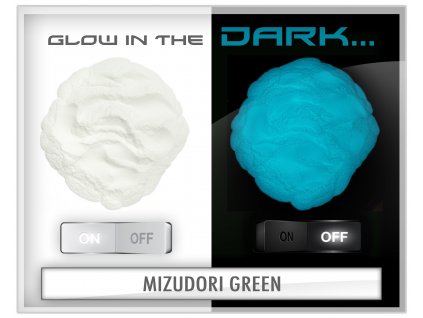

Bright blue, white-based glow pigment ideal for epoxy, acrylics, jewelry, slime, candles, and decor. Charges with light, glows for up to 8-10 hours.

Bright blue-green glowing pigment with long-lasting luminosity. Perfect for resin, acrylics, jewelry, slime, and more night-time projects.

Be the first who will post an article to this item!

Be the first who will post an article to this item!