EPOXYPLAST 100P Universal Resin 1,5 Kg

Code: 6498Related products

Construction polypropylene tape for the production of epoxy molds. Length 55m, width 60mm

High quality polypropylene tape for excellent separation of casting from mold, 48 mm x 66 m

Universal cleaning spray with 99.9% isopropyl alcohol for perfect degreasing and removal of dirt from electronics, glass, metal, plastic, and tools. Fast-drying, residue-free,...

Single-component solution designed for effective and quick removal and cleaning of surfaces from grease, oil, wax, dust, and similar contaminant.

Product detailed description

Universal laminating and potting resin EPOXYPLAST 100P

DIPON® EPOXYPLAST 100 P Universal Resin is a low viscosity and highly transparent epoxy resin for a wide range of applications such as glass resembling, color art, decorative applications or primers, stone carpets, carbon laminates, mold construction, aquariums and terrariums. EpoxyPlast 100 P Universal Resin impresses with its good clarity, very good self-venting and fast curing.

EpoxyPlast 100P Universal Resin is used where excellent UV protection is not required.

Key Features of EPOXYPLAST 100P Laminating Resin

- Highly transparent - improved new formulation

- Stable crystallization thanks to A/F technology

- Cast thickness 0.1-1 cm at 20°C

- Mixing ratio 2:1 by weight (resin : hardener)

- Processing time (20°C) approx. 30 min depending on the amount of material

- Recommended ambient temperature 15-22 °C

- Clear transparency in both components

- Low viscosity

- Non-toxic, BPA free, odourless

- Solvent free - VOC 0 g/L

- Self-leveling

- Excellent self-venting for a bubble-free surface

- Excellent substrate and backfill wettability

- Compatible with e.g. wood, concrete, glass, metal, fibreglass and carbon fibre, natural stone, silica sand, marble, granite

Small castings 0,1-1 cm

It enables casting of small castings up to 0.1-1 cm thick (at 20°C).

Processing time up to 30 min

The long processing time of up to 30 min provides sufficient time for mixing, pigmentation and debubbling of the mixture. Depending on the amount of material.

Ideal working temperature 15-22 °C

It cures at low temperatures as low as 15 °C. The recommended temperature should be 20 °C.

Primary use of EPOXYPLAST 100P epoxy resin

- Production of transparent or coloured jewellery from silicone moulds with a casting height of 1-10 mm (even larger casting quantities are possible depending on room temperature and the amount of material <19°C).

- Production of trays, coasters and much more.

- Production of glass and carbon laminates.

- For priming (penetrating epoxy resin) e.g. open pore wood (for river tables, lamp or furniture structures etc.), metal, concrete, screed.

- For the production of stone carpets, mortars, etc.

- For casting or lamination (e.g. spray lamination, pressing, infusion technique, vacuum, hand lamination)

How to use EPOXYPLAST 100P Universal Laminating Epoxy Resin

Always check that the epoxy resin component (component A) has not crystallized before starting work. For more information, refer to the datasheet under "Crystallization (milky, viscous or cloudy mass in component A)"

Application and Use

- EPOXYPLAST 100 P Universal Resin is accurately loaded into a clean container at a 2:1 mixing ratio by weight. A precision scale and two mixing containers are required for accurate weighing and mixing.Do not mix by volume as this may lead to an incorrect result.

- First mix components A and B at a maximum of 300 rpm for approximately 3-4 minutes.

- Mix A+B are then transferred to a new clean container and the residual resin from the edges of the old container is dripped into the new container .

- Stir again for 3-4 minutes. This process is important to obtain the most homogeneous mixture possible.

Cleaning

Use acetone or all-purpose thinner to clean used application items. Once the epoxy resin has cured, it can only be removed by sanding. It is recommended to clean immediately after use.

Recommendations for the use and storage of EPOXYPLAST 100P epoxy casting resin

- Resin should be stored in a dry place, minimum temperature 10 °C

- Protect from sunlight

- Keep out of reach of children.

- Resin and hardener should not be stored in an open container

- Application should be carried out where humidity is below 60% and temperature between 15 - 22 °C. If necessary, use a dehumidifier

- Resin should be used within one year of purchase

Important instructions and SAFETY

Crystallization (milky, viscous or cloudy mass in component A)

- Storage below 20°C may accelerate crystallization.

- Crystallized components are decrystallized by careful heating to approximately 55 to 70°C for several hours in a hot water bath, depending on the size of the container.

- In principle, it is important to keep the decrystallization time as short as possible.

- The maximum temperature should not exceed 70°C.

- After the epoxy resin (component A) has decrystallized, allow it to cool to a suitable processing temperature (15 - 20°C).

Safety Information and Documents

- Technical Data Sheet - Coming Soon

- Safety Data Sheet Epoxyplast 100P - Component A

- Safety Data Sheet Epoxyplast 100P - Component B

EPOXYPLAST 100P Component A

|

WARNING! Contains: 2,2-Bis[4-(2,3-epoxypropoxy)phenyl]propane, Reaction mass of 2,2'-[methylenebis(4,1-phenyleneoxymethylene)]dioxirane and 2-({2-[4-(oxiran-2-ylmethoxy)benzyl]phenoxy}methyl)oxirane and 2,2'-[methylenebis(2,1-phenyleneoxymethylene)]dioxirane(alkoxymethyl)oxirane (alkyl C12-C14)

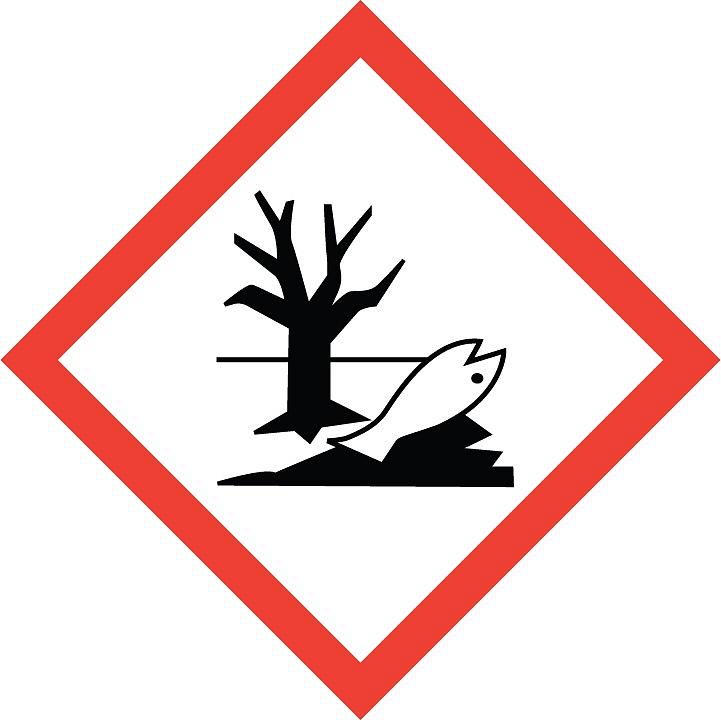

H315 Irritating to skin. H319 Causes severe eye irritation. H317 May cause allergic skin reaction. H411 Toxic to aquatic organisms, with long-lasting effects. P261 Avoid inhalation of dust/smoke/gas/mists/vapours/aerosols. P264 Wash thoroughly after handling. P272 Do not remove contaminated work clothing from the workplace. P302+P352 IN CASE OF CONTACT WITH SKIN: Wash with plenty of water. P305+P351+P338 IN CASE OF EYE CONTACT: Rinse gently with water for several minutes. Remove contact lenses, if fitted and if they can be removed easily. Continue rinsing. P362+P364 Remove contaminated clothing and wash before reuse. P333+P313 In case of skin irritation or rash: seek medical attention/treatment. P321 Professional treatment (see on this label). P337+P313 If eye irritation persists: Seek medical advice/treatment. P501 Dispose of contents/content in accordance with local/regional/national/international regulations.

UFI: GK80-S0T5-M008-Y09F

EPOXYPLAST 100P Component B

|

H302 Harmful if swallowed. H314 Causes severe skin and eye damage. H317 May cause allergic skin reaction. H412 Harmful to aquatic organisms, with long-lasting effects.P260 Do not breathe dust or mist. P303+P361+P353 IN CASE OF CONTACT WITH SKIN (or hair): Remove all contaminated articles of clothing immediately. Rinse skin with water [or shower]. P305+P351+P338 IN CASE OF EYE CONTACT: Rinse gently with water for several minutes. Remove contact lenses if they are in and if they can be removed easily. Continue rinsing. P310 Call the TOXIC INFORMATION CENTRE/physician immediately. P362+P364 Remove contaminated clothing and launder before reuse. P405 Store locked. P501 Dispose of contents/content in accordance with local/regional/national/international regulations.

UFI: DP80-90GJ-W00R-NAVH

Additional parameters

| Category: | Epoxy Resins |

|---|---|

| Weight: | 1.67 kg |

| EAN: | 4063636030793 |

| ? Epoxy System Type: | Epoxyplast 100P Universal |

| Color: | Highly transparent |

| Max thicknesses: | 1 cm |

| ? UV Resistance: | Medium |

| Casting Size: | Small Casting |

| Poměr míchání - váhový: | 2 : 1 (pryskyřice : tvrdidlo) |

| ? Doba zpracovatelnosti: | 30 min |

| ? Ideální pracovní teplota: | 15 - 22 °C |

| ? Hranice exhoterm: | 38 °C |

| Smrštění: | > 0,1 % |

| VOC: | 0 g/l |

| ? TG Ultimate: | 70 °C |

Clear casting epoxy resin for small castings, casting thickness 0.1 - 1 cm (at max 22 °C), cures from 15 °C, VOC 0 g/L, mixing ratio by weight 2:1, can be sanded after 2 - 3 days

Clear casting epoxy resin for small castings, casting thickness 0.1 - 1 cm (at max 22 °C), cures from 15 °C, VOC 0 g/L, mixing ratio by weight 2:1, can be sanded after 2 - 3 days

Two-component epoxy penetration on a dry substrate (humidity of the substrate up to 4%). The material is low-viscosity, solvent-free and nonylphenol-free.

Clear casting epoxy resin with maximum UV protection, casting thickness 1 - 10 mm, workability approx. 35 min, particularly low viscosity (very liquid), safe for contact with...

Clear casting epoxy resin with maximum UV protection, casting thickness 1 - 20 mm, one and a half times higher viscosity than LuminaCast 4 Gem Flow, workability approx. 60 min,...

Clear casting epoxy resin with food contact certification with maximum UV protection, casting thickness up to 10 cm, workability up to 240 min, low-viscosity (liquid),...

Clear casting epoxy resin with maximum UV protection, casting thickness 1 - 20 mm, one and a half times higher viscosity than LuminaCast 4 Gem Flow, workability approx. 60 min,...

Clear casting epoxy resin with maximum UV protection, casting thickness 1 - 20 mm, one and a half times higher viscosity than LuminaCast 4 Gem Flow, workability approx. 60 min,...

Clear casting epoxy resin with maximum UV protection, casting thickness 1 - 20 mm, workability approx. 45 min, highly viscous - thick, safe for contact with food, mixing ratio...

Clear casting epoxy resin for large castings, casting thickness up to 10 cm (at max 20 °C), cures from 10 °C, hardness 81 SHORE D, VOC 0 g/L, mixing ratio by weight 2:1, full...

Clear casting epoxy resin for medium casts, casting thickness 0.1 - 5 cm (at max 20 °C), cures from 15 °C, hardness 81 SHORE D, VOC 0 g/L, mixing ratio by weight 2:1, can be...

Clear casting epoxy resin for medium casts, casting thickness 0.1 - 5 cm (at max 20 °C), cures from 15 °C, hardness 81 SHORE D, VOC 0 g/L, mixing ratio by weight 2:1, can be...

Clear casting epoxy resin for medium casts, casting thickness 0.1 - 5 cm (at max 20 °C), cures from 15 °C, hardness 81 SHORE D, VOC 0 g/L, mixing ratio by weight 2:1, can be...

Be the first who will post an article to this item!

Be the first who will post an article to this item!

| Manufacturing company : | DIPON.DE Removable Automotive Coatings GmbH & Co. |

|---|---|

| Address : | Ringofenstr. 39 I 44287, Dortmund, Deutschland |

| E-mail : | info@dipon.de |